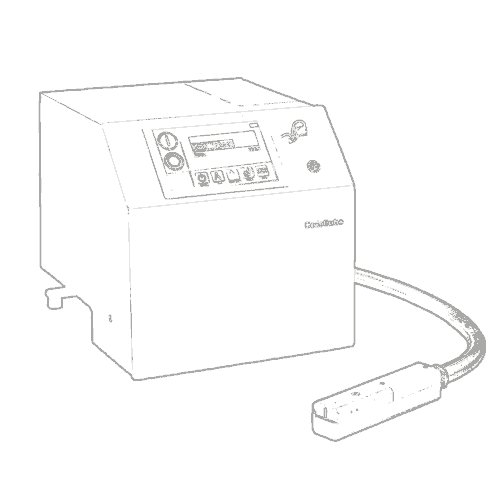

CIJ Printer Use

CIJ printers are used for printing codes and other data on packaging, including food, plastic bottles, glass bottles, and paper packages. CIJ printers are also useful for marking items that need to be certified, such as electronics and security devices. CIJ printers also can print ingredient lists on plastic bottles, and can even print on curved surfaces. These advantages make CIJ printers popular for many different types of applications.

The technology behind a continuous inkjet printer is not new. It has been used for decades for marking and coding applications in many industries. These printers print on any surface, including metal, plastic, and wood. They also have excellent versatility and are ideal for manufacturing processes involving the coding and marking of various kinds of products, from food to lumber. What makes them so versatile is their ability to print on nearly any surface, whether it is flat, curved, or irregular.

In CIJ printers, the ink is combined with a make-up liquid. This make-up liquid is separate from the actual ink and is mixed in an ink reservoir. The ink then flows under high pressure through the print head. A resonator in the print head causes vibrations in the ink jet. As these drops move through the print head, they combine with the coding. When the cij printer has finished, the unused droplets are returned to the reservoir.

CIJ printing is also a popular choice for printing lot numbers and product codes on electronics. These components are often delicate and require permanent markings. Printing these codes ensures traceability of these parts. A permanent, high-resolution CIJ printer can print a digit character with 600 dpi on a surface. In the automobile industry, traceability is also important. Printing identification numbers and production codes can help to identify parts that are defective or have been assembled incorrectly.

What Type of Ink Does a CIJ Printer Use?

CIJ printers are useful for printing on primary packaging. They can be used to print lot numbers and expiration dates. They can be integrated into automated filling machines. Furthermore, CIJ printers have a small footprint, and they can be easily integrated with an automatic filling machine. They can also be used to print on curved surfaces, including film that has been sealed with a seal.

CIJ printers are also capable of printing on dark backgrounds. Moreover, they can print clear and legible characters on a wide variety of materials. They can also handle a wide range of coding, such as 8-line printing and 64-dot coding. All CIJ printers are built with safety in mind. These printers are designed to withstand the high-speed printing without sacrificing print quality.

CIJ printers use two different types of inks. The most common is aqueous ink, which is made up of water, dyes, and glycol. Aqueous inks are difficult to control on media. Pigment-based inks are more expensive and do not last as long. However, they last longer than their aqueous counterparts.